The Advantages of In-House 3D Printing Wax Patterns

In-house 3D printing of wax patterns for investment casting is revolutionizing the manufacturing industry. With the advancement of technology, companies can now take control of their design processes, enhance intellectual property protection, and enjoy faster turnarounds, all while benefiting from the ease of use, low cost of ownership, and exemplary technical support from Romanoff.

Keep Designs In-House

One of the most significant advantages of in-house 3D printing wax patterns is the ability to keep designs within the company. This ensures that you have full control over your design iterations, modifications, and final outputs. No more waiting for external vendors to deliver your prototypes or fearing that your innovative designs might be leaked. Everything stays within the secure environment of your own facility.

Fast Turnaround

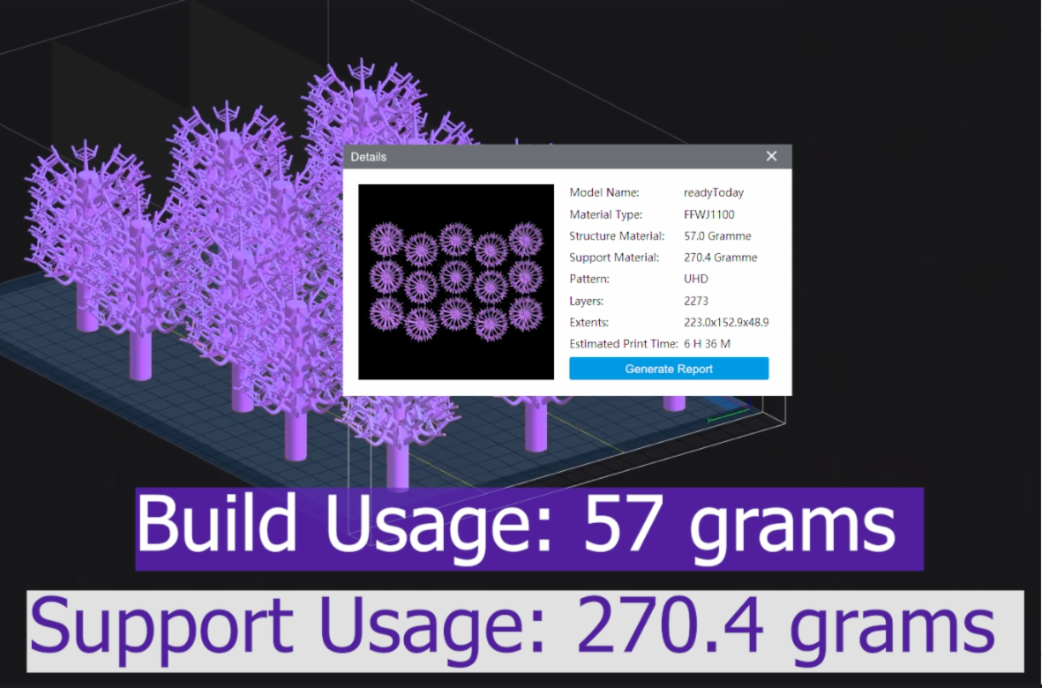

In-house 3D printing drastically reduces the time needed to produce wax patterns. Traditional methods such as manual wax injection and mold making can be slow, involving multiple steps and coordination with external suppliers. With a 3D printer at your disposal, you can quickly move from digital design to physical model, accelerating your development cycles and bringing products to market faster than ever. Watch us print and entire 3D printed casting tree!

Ring Setting Tree Build Statistics

|

Build Material Cost: |

$0.55 per gram |

|

Support Material Cost: |

$0.16 per gram |

|

Total Build & Support Cost: |

$71.15 |

|

Number of Settings: |

600 Total |

|

Settings per Tree: |

40 Settings |

|

Number of Trees: |

15 Trees |

|

Cost per tree: |

$4.97 per tree |

Ease of Use

Flashforge WaxJet 3D printers are designed with user-friendliness in mind. Even if your team has little to no experience with 3D printing technology, they can quickly learn to set up and load an STL operate these machines thanks to intuitive interfaces and comprehensive user manuals. This ease of use means you can get started with minimal training and immediately begin reaping the benefits of in-house production.

Low Cost of Ownership

Owning a WaxJet 400 HD from Flashforge is an investment that pays off in the long run. The initial cost of purchasing a Flashforge WaxJet 400 HD is offset not only by the savings from not outsourcing your pattern production, but also from the vastly more cost effective of the build and support material when compared to traditional manufacturing methods or similar technologies, making 3D printing your wax patterns a viably smart solution for companies of all sizes! Check out the material cost savings below compared to the competition!

|

FlashForge WaxJet 400 HD |

Competing Technology |

|

|---|---|---|

|

Ring Quantity |

227 |

227 |

|

Run Time |

5 hrs 10 min |

16 hrs 27 min |

|

Support Material Usage |

234.9 g |

416 g |

|

Build Material Usage |

61.5 g |

98 g |

|

Material Cost per Job |

$33.83 (Build) $37.59 (Support) |

$124.80 (Build) $65.66 (Support) |

|

Cost of Build and Support Material per Bottle |

$1,650 / 3.0 kg bottle (Build) $590 / 3.6 kg bottle (Support) |

$1,005 / 1.5 kg bottle (Build) $482 / 1.6 kg bottle (Support) |

|

Cost of Build and Support Material per Gram |

$0.55 / gram (Build) $0.16 / gram (Support) |

$0.67 / gram (Build) $0.30 / gram (Support) |

Romanoff's Technical Support

Another outstanding benefit is the technical support provided by Romanoff. Known for their expertise and commitment to customer satisfaction, Romanoff offers extensive support to ensure that your 3D printing operations run smoothly. Whether you encounter technical issues or need advice on optimizing your prints, their team of experts is always ready to assist, giving you peace of mind and helping you maximize the potential of your in-house 3D printing setup.In-house 3D printing of wax patterns presents a myriad of benefits that can transform your manufacturing process.

By keeping designs in-house, protecting intellectual property, enjoying faster turnarounds, maintaining a low cost of ownership, and relying on Romanoff's exceptional technical support, you position your company for success in today's fast-paced and competitive market.

Adopting this innovative approach not only enhances your operational efficiency but also strengthens your capability to deliver high-quality products quickly and securely. It's time to embrace the future of wax 3D printing Flashforge Wax 3D Printers and Romanoff International!

Comments

Leave A Reply

Your email address will not be published.