View Previous Page

How to Re-Calibrate the Internal Pointer from Software

This guide will show you how to recalibrate your ElettroLaser Laser Engraver from within the laser software.

1. From the software, create a 90mm x 90mm square (in case you don’t have such a large plate, you can choose a size starting from 50mm x 50mm upwards) and we will engrave it. ( Fig.1)

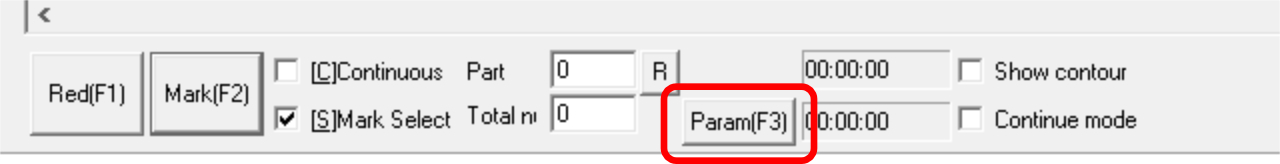

2. Once engraved, without moving the underlying plate, let’s repeat the preview and check that the position and dimension are coordinated with the previous engraved result, otherwise you have to move/enlarge the preview from the software ( Step 3)

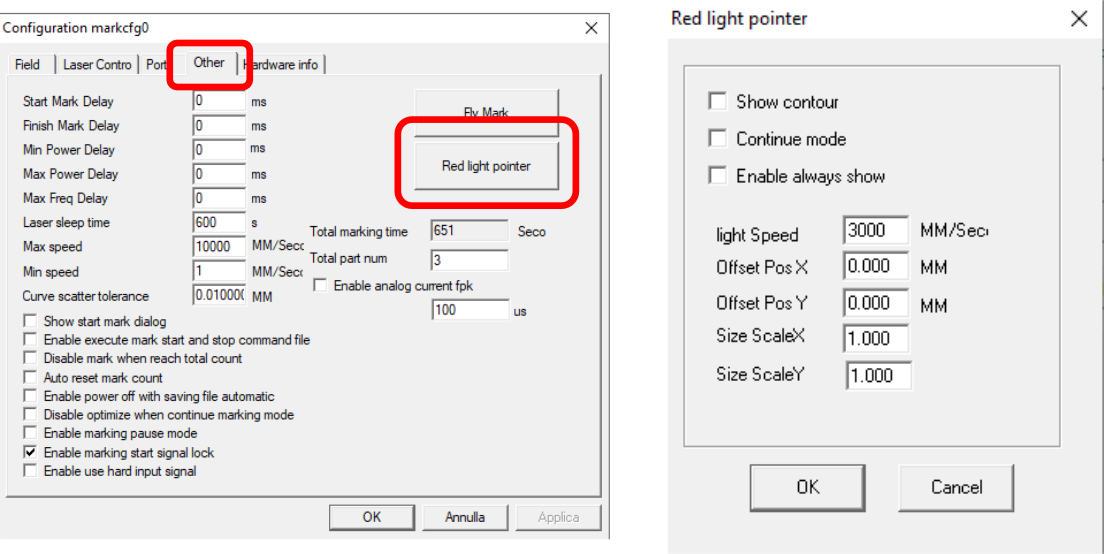

4. In the menu that has just appeared in the pop-up window, we’ll find the settings that we needed for the preview editing:

- - Offset Pos X

- - Offset Pos Y

- - Size Scale X

- - Size Scale Y

The OFFSET POS X function will allow you to move the preview on the X axis (therefore from right to left) simply by entering a value in millimeters (example: inserting -0.05 will move the preview by 0.05mm to the left; 0.05 will move the preview of 0.05mm to the right)

The OFFSET POS Y function will allow you to move the preview on the Y axis (therefore up or down) simply by entering a value in millimeters (example: inserting -0.05 will move the preview down by 0.05mm; 0.05 will move the 0.05mm upward preview)

The SIZE SCALE X function will allow you to enlarge or shrink the size of the preview on the X axis to calibrate the preview on the previously engraved square.

The SIZE SCALE Y function will allow you to enlarge or shrink the size of the preview on the Y axis to calibrate the preview on the previously engraved square.

Whenever a change is made on one of the values, it is important to apply it and check if the result is what you want, otherwise you can change it again.

A piece of advice that we would like to give is to calibrate element by element without making changes to all the values at the same time. In case of need, do not hesitate to contact us at 631-842-2400 or via email at support@romanoff.com