Flashforge 400 HD: Triple Printhead Jewelry Wax 3D Printer

| Specification | |

|---|---|

| Brand | Flashforge |

| Model | 400 HD |

| Printheads | Triple Print Head System |

| Build Plate Volume Dimensions LWH: | 289 x 218 x 150 mm (11.4 x 8.6 x 5.9 in) |

| DPI Resolution (Dots Per Square Inch) XYZ | 1200 x 1200 x 1600 |

| Dimensional Accuracy | ±0.04 mm/20 mm |

| Standard Power Supply | AC 220-240V, 4KW, 20 amp |

| Optional Power Supply | 110V, 30 amp Transformer |

| Machine Dimensions LWH | 1352 x 775 x 1600 mm (54 x 31 x 64 in) |

| Crated Machine Dimensions LWH | 1530 x 900 x 1837 mm ( 61 x 36" X 73") |

| Uncrated Weight | 480 kg (1058 lbs) |

| Crated Weight | 630 kg (1389 lbs) |

FlashForge WaxJet 400 HDis a cutting-edge, large-scale 3D printer engineered for precision and versatility, designed to meet the demands of advanced manufacturing. This innovative machine excels in producing intricate wax patterns with exceptional smoothness and detail, making it ideal for applications in jewelry design, fine crafts, precision casting, and aerospace components.

Key Advantages

- 3 Print Heads - Produces parts 3 times faster.

- High Resolution - Offers a print resolution of 1200 x 1200 x 1600 dpi in XYZ axes.

- Efficient Support Structure - Utilizes a honeycomb support structure to reduce the amount of support wax used.

- Build & Suport Material Costs - Between 20-50% lower.

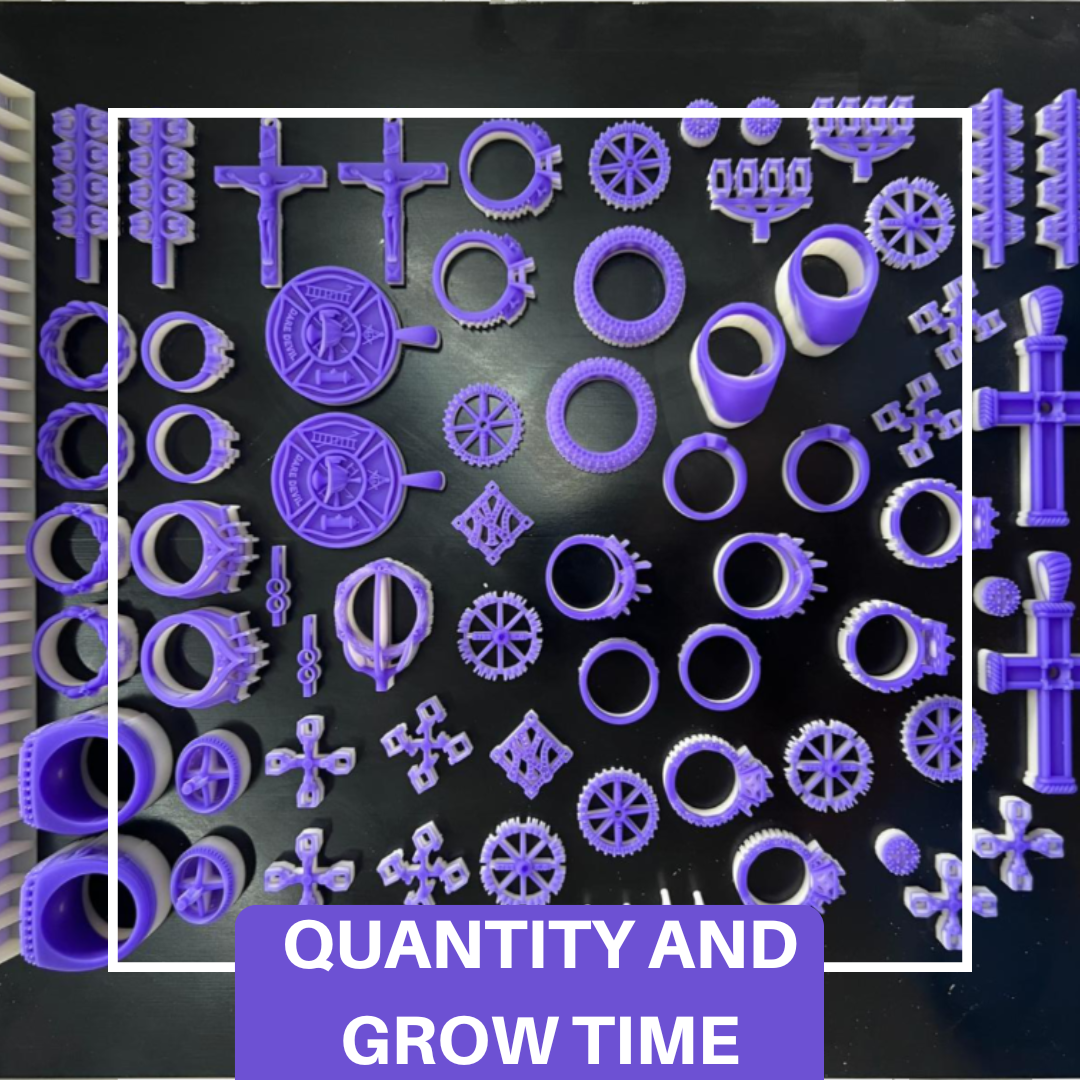

- Advanced Build Material - Features a new flexible purple wax build material.

- Low Maintenance - Designed with fewer moving parts, resulting in less maintenance and downtime.

- Remote Access - Equipped with Windows-based software for remote operation.

- Durability - Enhanced with added support for stone-in-place casting.

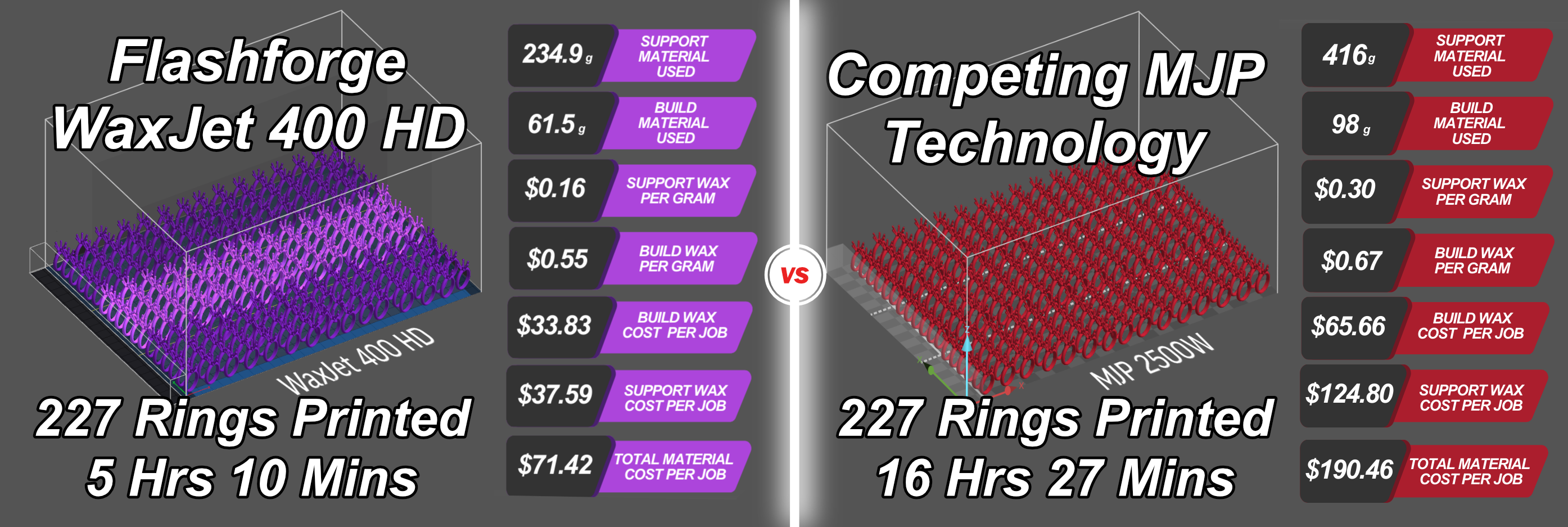

- Cost-Effective - Uses 20% less build and 60% less support material per job compared to competing technologies.

- Cost Savings - Eliminates the need for mold-making and retouching.

Triple Printhead Jewelry Wax 3D Printer

High Precision

3 Industrial-Grade Printhead: The high-precision printhead and 1um-grade motion control ensure detailed and creative outputs. With 3 Printheads, the Flashforge 400 HD print on full plate(227 rings) under 6 hours. The speed is combined with high resolution models with less lines and easier to handle is what makes the 400 HD the best 3D Wax Jewelry Printer in the market today.

Ultra Productivity

High Output: Capable of producing 10KG of wax patterns in a single month.

The WaxJet 400 HD stands out with its high-precision, multi-jet technology, capable of creating smooth and finely detailed wax patterns. It offers significant advantages over similar technologies, including faster production times, reduced material usage, and lower maintenance costs.

View Product to explore the full capabilities and advantages of the Flashforge WaxJet 400 HD.

| How 400 Printer Competes with Similar Techonology | ||

|---|---|---|

| FlashForge WaxJet 400 HD | MJP 2500W | |

| Ring Quantity | 227 | 227 |

| Run Time | 5 hrs 10 min | 16 hrs 27 min |

| Support Material Usage | 234.9g | 416g |

| Build Material Usage | 61.5g | 98g |

| DPI | 1200x1200x1600 | 1200x1200x1600 |

| Resolution | 16um | 16um |

| Support Cost Per Job | $37.59 | $124.80 |

| Build Cost Per Job | $33.83 | $65.66 |

| Cost Per Bottle (Build) | $1,650 per 3.0k bottle | $1,005 per 1.5k bottle |

| Cost Per Bottle (Support) | $590 per 3.6k bottle | $482 per 1.6k bottle |

| Cost Per Gram (Build) | $0.55 | $0.67 |

| Cost Per Gram (Support) | $0.16 | $0.30 |

| Printhead Jets | 880 x 3 | 880 |

| Packing Qty | Priced individually |

|---|

Log In