What Causes Porosity: The Facts

What Causes Porosity: The Facts

BY: BOB ROMANOFF

The causes of porosity today are still shrinkage and gas, just as they were when I wrote my first article on porosity in 1976. However, most of the porosity that we see in jewelry castings today is shrinkage porosity, which results from the metal contracting during freezing and solidification.

There is a difference in appearance between shrinkage porosity and gas porosity. Gas porosity generally shows up on the surface of castings—let's say rings—as irregularly-shaped bubbles as opposed to the pinpoint or wormlike porosity which results from shrinkage. The worm-like shrinkage porosity generally shows on the surface only as a small pinpoint, or in a raw casting as a dark spot on the in-side or outside wall of a ring. When that ring is polished, that small pinhole then sinks into the surface of the casting and either shows up as a single "worm" or the entire surface shows up as a generally spongy area. Under magnification, shrinkage porosity shows up as a fernlike, crystal-line structure known as dendritic growth. It is not uncommon for people to confuse shrinkage porosity with gas porosity. Some shrink-age porosity might also be confused with what is known as a "hot tear," which is completely different and will be explained later in this article. Gas porosity can also occur in the same piece along with shrinkage porosity and hot tears, although all three usually occur only in the heavy sections of the casting.

The most common causes of shrinkage porosity can be found in the design of the jewelry piece itself—primarily in very abrupt changes from heavy sections to thin sections, or vice-versa. It can also occur when the sprues that are used are too small and insufficient to keep the hot molten metal feeding the area of the ring which is cooling and shrinking. Another cause of shrinkage porosity is the placing of castings too close together in the flask; this makes it more difficult for the heat to escape through the investment and doesn't allow for the rapid chilling of the castings. Relatively slow cooling of the castings promotes porosity.

Shrinkage is a feeding problem. One way to recognize if the shrinkage porosity is caused by either incorrect flask temperature or metal casting temperature, as opposed to improper sprueing or feeding, is to evaluate the porosity. If the same rings show up with porosity in the same area on a consistent basis, that is generally an indication that the ring is fed insufficiently and/or improperly. If the location of the shrinkage porosity is different from tree to tree of the same style ring, then the cause is probably the inconsistency in the temperature of the metal or the flask.

The ideal sprue or feed attached to a ring should be designed to promote progressive solidification. This means that the heaviest part of the casting is fed directly by a slightly heavier sprue, and the sprue in turn is fed by a still heavier sprue (for instance the center “tree trunk" of the wax tree); that, in turn, eventually leads to the button at the bottom, thereby encouraging the shrinkage to take place progressively toward the bottom of the cast. In a correctly designed combination of sprue and ring, the first place to solidify should be the casting. If this progressive solidification does not occur, then the shrinkage will probably take place in the ring.

Casting temperature as well as flask temperature is also extremely important.

Flask temperature: In order to minimize the variables in casting, I usually recommend that a caster keep his flask temperature constant for everything he will cast in a particular oven. The reason being that, although he may change the temperature of his controller, the only thing that really changes in temperature in ten to 15 minutes are the temperature of the oven; the interiors of the flasks actually take a minimum of 30 to 60 minutes (depending on their size) to change to the new desired temperature. Therefore, there is no practical way for the caster to know exactly at what flask temperature he is casting if changes are made unless a temperature probe is actually inserted into the flask when removed from the oven. I generally recommend a flask temperature of 800°F (427°C) (Thicker designs) to 1000°F (538°C) (Thinner designs) be used, depending on the thickness of the castings. These numbers generally apply to gold, alloys and silver. Platinum flask temperatures are from 1600°F to 1650°F. Sometimes a flask temperature of 1000°F (593°C) to 1200°F (649°C) is required for thin sterling castings due to the nature of the metal.

AS A GUIDE: Casting temperature: There are four basic temperature ranges in which metal may flow into a flask. Each range will produce different results. In order to find the temperature at which perfect castings can be produced, you must first know the melting point of the alloy you are casting.

- A. The first temperature range is from the melting point of the alloy up to about 75°F above the melting point. This range will sometimes produce incomplete castings because the metal is too cold to form a complete casting. Usually everyone diagnoses this problem easily.

- B. The second range is the one most people misidentify: It is usually about 75°F to 150°F above the melting point. The metal flows into the investment and forms a complete casting, but it is not hot enough to remain fluid when both streams of metal meet in the case of a ring. (When metal flows into the shank of a ring from a bottom sprue-the usual location –it divides and flows around both sides of the shank; one side flows around 75% of the ring, while the other side of the shank only receives about 25% of the flow.) The result is that the two independent streams of metal meet on one side of the shank. The result of these two streams meeting together in a semi-fluid state produces “Cold Porosity” In effect, these two streams have met and solidified before they became a “solid homogeneous casting”. Most people will try casting at a lower temperature, which worsens the condition and results in incomplete castings.

- C. The third temperature range is a very narrow range of 30°F to 40°F above the second range. It is during this range that the metal will flow into the investment at a temperature just hot enough for both streams of molten metal to meet in a completely fluid state. If the technique of progressive solidification (described earlier in this article) is followed in this desired temperature range, the result should be a good casting. (Getting a perfect casting depends on other factors also)

- D. The fourth range is all temperatures above the third range. This will result in a ring which certainly fills in completely, as in the third range, but being hotter in temperature than necessary, produces shrinkage as it cools down to its solidification temperature. As the casting temperature increases in the fourth range, the shrinkage in the heavier parts of the casting will be greater. It is extremely important to remember that the temperatures mentioned in these four ranges are to be used as a guide only. Other factors such as sprue diameter and length, flask temperature, type and thickness of castings etc., will determine the exact temperature for producing perfect castings.

Hot tears: Hot tears are related to very high internal stresses on the casting. They occur when a section of the casting is unable to expand or contract as the metal is cooling and shrinking in its normal manner. Most of the time hot tears are caused by an abrupt change: for example, going from a heavy section of the casting to a thin section of the casting while making a sharp bend. The methods for eliminating or minimizing hot tears are: 1) To design the model so that there are no heavy and thin sections occurring at a point where there is a sharp bend in the casting; 2) to add a sprue to the heavy section which would allow the metal to feed more easily through that section of the casting, minimizing the stress placed on the casting at that point; 3) to change alloys; some alloys have more shrinkage than others, thereby creating additional stresses. The solution to hot tear problems has often been a simple change of alloy.

ILLUSTRATIONS

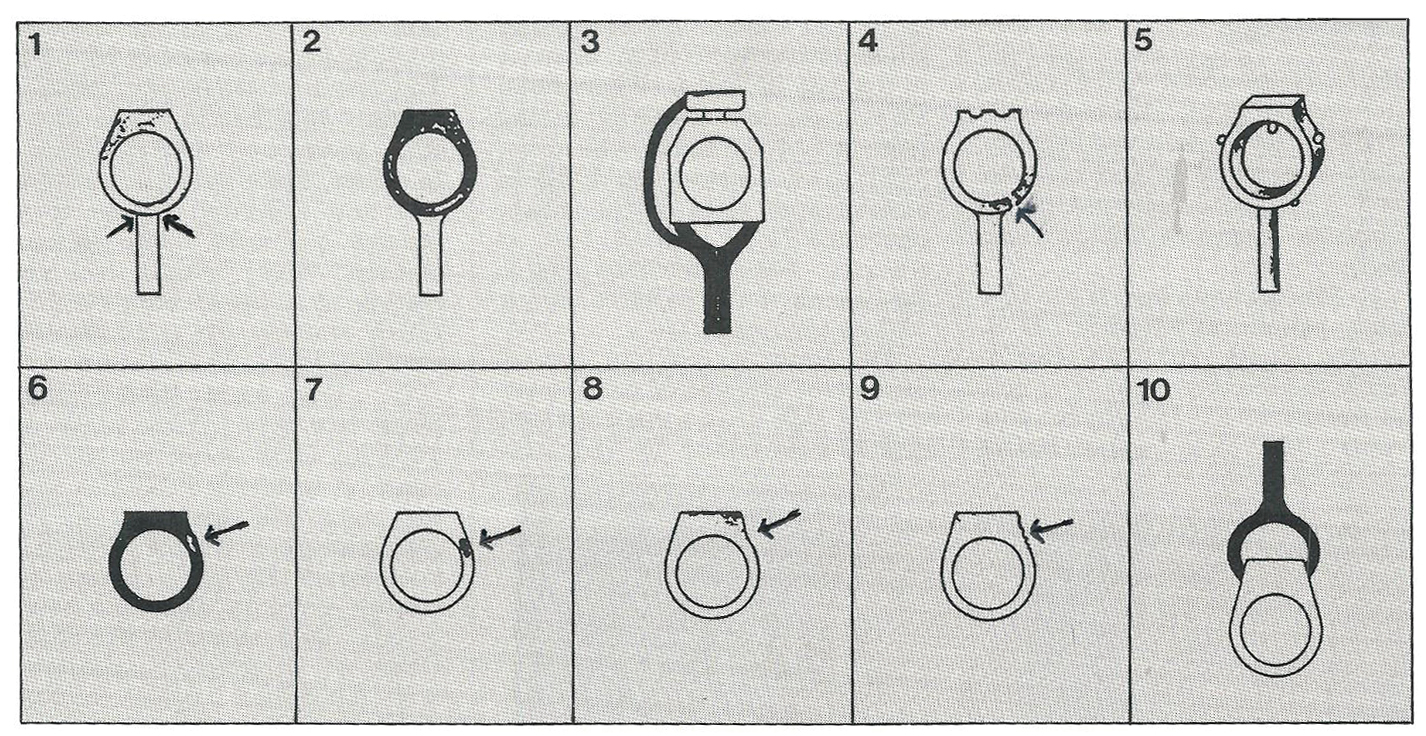

The above illustrations indicate some common problems.

- Diagram 1 shows the incorrect way for a sprue to enter a ring. There are 90° corners, as indicated by the arrows. When the metal enters this ring, a certain amount of turbulence will be created; this will definitely result in a pickup of air which is being introduced into the ring cavity. The proper method of having a sprue enter a ring or any other jewelry design is to have a flared entrance, as in diagram 2. There, the sprue is flared, so that a smooth and uniform flow of metal will be able to enter the casting without turbulence. The sprueing technique illustrated in diagram 3 shows sprues being used to enter the three heaviest portions of that particular casting; this will allow the heaviest portions to be fed sufficiently to minimize the shrinkage porosity described earlier in this article, If the metal entered only one of those particularly heavy areas, it would then have to travel through several thin areas before getting to the other heavy areas. The result would be that the most shrinkage would take place in the heavy areas, since the thin areas leading to those heavy areas would freeze and solidify first, thus cutting off the source (feed) of molten metal required to minimize the shrinkage.

- The ring in diagram 4 is an example of the second temperature range referred to earlier whereby the two metal streams have not met to form a homogeneous casting at that particular point because the metal was not hot enough for the two streams to solidify together. This symptom would also indicate a "hot tear."

- The ring shown in diagram 5 shows some balls on the inside and outside of the ring — the result of insufficient or improper vacuuming of the investment. Either the operator's vacuum pump was not strong enough, or insufficient time was allowed for the air to escape the investment. It would also have helped if the wax patterns were dipped in a liquid such as Vacufilm to reduce the surface tension of the wax and, therefore, allow the air bubbles to leave the wax surface more easily.

- The ring in diagram 6 shows a white inclusion in the casting, most probably investment particles. This is the result of investment breaking off at the entrance of the tree when the metal entered.

- The ring in diagram 7 shows a black spot in the casting, most probably a graphite inclusion. Here, graphite flaked off from the inside wall of the crucible because the crucible was used beyond its normal life or was a poor quality graphite.

- The ring in diagram 8 is probably an example of a casting which was made from a wax pattern that had shrunk considerably. The wax operator did not notice the shrinkage in the wax surface before setting the ring up on the wax tree. This is quite common in a design where there is a large, broad, flat surface which encourages shrinkage on the surface of the wax. The easiest way to eliminate this problem is for the operator to hold the mold against the wax injector nozzle for a sufficiently long period of time (minimum period is 30 to 40 seconds) so that the wax solidifies before the mold is removed from the nozzle. This would allow the wax to solidify while the wax is under pressure, thereby eliminating the "sink" in the surface of the wax. You might use a wax with a faster setting time. Automatic vacuum wax injectors can be programmed to control this.

- Diagram 9 can be the result of an improper burnout cycle. The problem can be that this operator has allowed the temperature in the oven to climb too rapidly during the first hour, so that the wax, instead of melting out smoothly and easily from the tree, has boiled in the cavity and broken down the surface of the investment to which it was immediately adjacent. The result is the rough surface that you see.

- The ring in diagram 10 has a double sprue entering a very heavy section at the top of a signet ring. Many people use this type of sprue, but 1 believe that it would be better to have a single, heavy sprue, one to one-and-a-half times the size of the area which it is directly feeding.

GAS POROSITY

Gas porosity in castings results from gases being absorbed into the metal during the hot molten state and remaining when the casting become chilled and solidified. To prevent gas porosity, one must first prevent gases from being introduced into the molten metal by melting in a controlled atmosphere (vacuum and then argon). In the event some gases are introduced into the molten metal, their escape, before the casting solidifies, should be made as easy as possible. First let us look at the introduction of the gases.

Metal, while in its molten state, is constantly trying to absorb gases such as oxygen and hydrogen. If we use a protective atmosphere for the metal, this will minimize the introduction of gases into the casting. An example of a protective atmosphere would be the introduction of argon gas after melting the metal in a vacuumed chamber. The argon, since it is heavier than air, tends to form a blanket over the molten metal, thereby preventing gases from being absorbed by the molten metal. Melting the metal in a graphite crucible minimizes absorption of gases since the graphite crucible produces what is known as a “reducing atmosphere”

Molten metal will hold many more times the volume of gas than will remain dissolved in the solidified casting. During solidification of the casting, this gas may escape if the conditions are right; if not, it will remain in the casting and show up as gas on the surface.

During centrifugal casting, the centrifugal forces behind the molten metal actually help to push the gases out of the casting and into the surrounding investment, assuming the investment is porous enough to allow the gases an easy escape. A vacuum Casting machine with overpressure will do the same. The investment will be more porous and allow the gases to escape if the burnout has been done properly. If the investment is chalk white, all of the wax and ash residues have been completely burned out; therefore the investment will allow the gases to escape through the investment wall quite easily. Insufficiently or improperly burned out wax and ash residues will act as barrier and trap gases in the castings.

Other that the centrifugal force pushing the gases out of the castings, or overpressure in a Vacuum Casting Machine, it helps to minimize the outside pressure on the walls of the investment by also pulling a vacuum on the flasks. Allowing a strong vacuum to pull on the walls of the investment, such as through perforated flasks, minimizes the back pressure on the investment, thereby making it easier for the gases to escape through the investment. If these forces are not exerted on the gases, they will probably remain in the casting to show up as gas porosity and become a part of the finished piece.

The reason it is best to use at least a 50/50 mixture of fresh to re-melted karat gold alloy is that the zinc in the alloy tends to burn out with each melt. The zinc acts as a deoxidizer, so when it is lost in re-melting, that property is lost as well (unless the zinc can carefully be added back in).

Sprues should be round, smooth and preferably straight in order to minimize the entrapment of gases on the way into the casting; gas entrapment will occur if sprues are required to make 90 o bends, which create unnecessary turbulence.

Crucibles and furnace walls absorb moisture. This moisture is then transformed into gases. The solution is that all crucibles and furnaces should be heated before they are first used to eliminate any moisture that may be in them.

It is important that the flask temperature be hot enough that the outside surface of the casting does not solidify before the inside surface. If the flask temperature is not hot enough, a wall will form around the casting, making it difficult if not impossible for any gases that have accumulated in the molten metal to escape before the piece completely solidifies.

Ideally you should want to melt metal as quickly as possible; bring it to the correct temperature, and then cast it into the flask at the moment that it reaches the optimum temperature.

Gas absorption in molten metal is really a factor of time and temperature. As the temperature of the molten metal increases and remains at a high point for a long period of time, more gases will be dissolved.

Most casting machines used today melt the metal in a vacuumed atmosphere and then introduce argon gas at the right moment. (The right moment is just before zinc in the alloy would begin to vaporize out of the alloy) When the desired molten metal temperature is reached as determined by an immersion thermocouple, then the thermocouple, and its protective tube, lift and the metal drops into the flask, (which is under vacuum). Then overpressure and vibration begins so that the conditions are all ideal for a perfect casting.

Log In