Indutherm MC60V Gold Casting Machine

| Indutherm Casting Machine | |

|---|---|

| Brand | Indutherm |

| Model | MC60V |

| Power | 3.5kW / 230 V single-phase 16A, 50 or 60Hz |

| Temperature Max | 2372ºF (1300ºC) |

| Thermocouple Max Temperature |

Type N 1300ºC |

| Training | Technical Training & After Sales Support Available |

| Casting Volume | up to 450g Au 18kt Gold & 300g Silver |

| Compatible Flasks (D X H) | 3 (or 4") x 5" (80/100 mm x 120 mm) |

| Machine Dimensions | 15" x 17" x 17" (400 x 450 x 450 mm) |

| Crated Dimensions (Lx W x H) |

32" x 47" x 32" inches (812 x 1193 x 812 mm) |

| Crated Weight | 130lbs (59 kg) |

| Uncreated Weight | 70.5 lbs (32 kg) |

| Country of Origin | Germany |

The Table Top Casting Machine MC 60 V

Compact Solution for Small-Series Casting in Precious Alloys

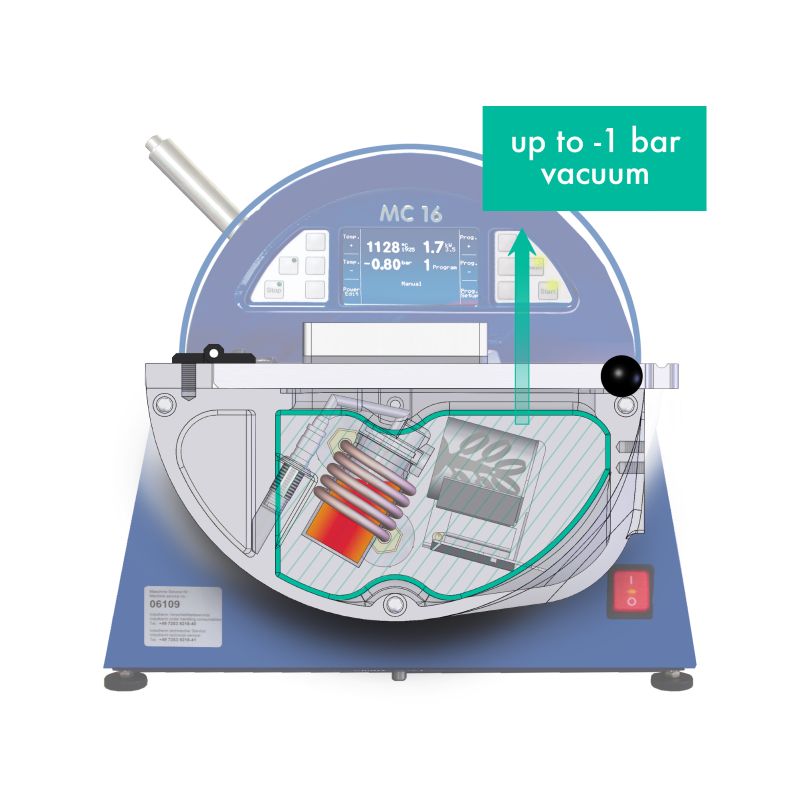

The MC 60 V is designed for users who find the MC 16 too small but do not require the larger, more manual VC series machines (e.g., the VC 400). This high-performance, compact casting machine is perfect for smaller production quantities and is suitable for various jewellery alloys such as gold, silver, copper, and bronze, as well as brass and aluminium alloys. With its vacuum and overpressure functions and numerous automatic control features, the MC 60 V delivers first-class castings with minimal effort, making it ideal even for beginners.

Rapid and simple casting

The entire casting process can be performed easily, quickly, and safely, even without prior technical knowledge. In the investment machine, the gypsum is mixed under vacuum, ensuring accurate dosing and a bubble-free mixture. The flask containing the wax model is also filled under vacuum, with vibration during filling to eliminate air inclusions. The wax is then melted off in the furnace, and the mold is burnt out.

For small series and single castings

A key advantage of the MC 60 is its ability to quickly cast master models or semi-finished materials in any desired shape, providing independence from large casting departments. Its compact size and comprehensive features make it an excellent solution for studios and goldsmith workshops with limited space.

Easy of Use & Quick Casting

The whole process of casting can be carried out simply, quickly and safely without any real prior technical knowledge of casting. With the MC 60 V – and with all MC machines – you can easily cast by hand from the crucible to your mould and feel what you are doing – just as it has been done for thousands of years. So that this works consistently and safely, the entire melting/casting unit is tilted together through a 90° angle.

For perfect balance and to make do with as few moving parts as possible, almost the whole machine moves during tilting: being cylindrical in design, the whole moving section rotates as if in a halfpipe – ingeniously simple and stylishly designed on high-quality rollers.

However, unlike manual casting, the process takes place in an enclosed chamber under a vacuum or inert gas atmosphere, to prevent air pockets and oxidation. You can check the melting and pouring-off process through the sight glass.

Full text LCD display for fine adjustment and serial programming

MC60 can melt and cast silver (300 g), gold (450 g, 18 ct.)

MC60 is a small device with a base 400x400 and 470 mm high and 30 kg weight.

Main benefits

- Very simple use, short training period, very good results even by operators with less experience in casting techniques

- Excellent price-performance ratio

- 3,5 kW generator enables quick melting periods

- Thorough mixing of metal by induction generator (low frequency tuning)

- Melting under vacuum for reduced danger of oxidation

- Excellent mould filling because of inert gas / over-pressure, max. 2 bars

- Low running costs because of inexpensive consumables and the use of flasks without flange

- NEW: LCD-display with all programm data

- NEW: vibration technology

- Excellent ratio machine size to capacity: flasks up to Ø 100 mm x 120 mm h

Specifications:

Model MC 60

Furnace type/furnace power Induction - 3.5 kW

Max. melting point - 1300°C

Volume - 450 g (18ct Au)

Crucible type - Ceramics/Graphite

Max. cell size - Ø 80 mm, 120 mm

Poer supply -230 V

Compact High-Performance Casting Machines

The MC60V has been developed with the user in mind for whom the MC16 is too small but a simple machine from the large VC series (e.g. the VC 400) is too big or requires too much manual operation. This small high-performance casting machine is ideal for smaller production quantities and can be used for jewelry alloys such as gold, silver, copper, and bronze, as well as for alloys of brass and aluminum. Thanks to the vacuum and overpressure functions and the many automatic control features, the machine provides first-class castings with little work – suitable for “beginners”.

|

|

|

|

|

|---|---|---|---|---|

| Specification | MC16 | MC20V | MC60V | MC100V |

| SKU | 78-2050 | 78-2100 | 78-2200V | 78-4500 |

| Maximum Power/Electrical | 3.5 KW 230V Single Phase | 3.5 KW 230V Single Phase | 3.5 KW 230V Single Phase | 8 KW 3x400V |

| Maximum Temp | 2000°C | 2000°C | 1300°C | 2000°C |

| For Flasks Up To | Ø 30/50/65/80 mm x 80mm h | Ø 30/50/65/80 mm x 80mm h | Up to Ø 80/100 mm x 120mm h | Up to Ø 80/100 mm x 120mm h |

| Casting Volume | 100 g Au 18ct 110g steel/200 g Pt | 100 g Au 18ct 110g steel/200 g Pt | 450 g Au 18ct 300 g Ag 925 | 450 g Au 18ct 250 g Steel 500 g Pt |

| Control Panel | LCD, Full Text Readout | LCD, Full Text Readout | LCD, Full Text Readout | LCD, Full Text Readout |

| Auto Vacuum/Over-Pressure | Standard | Standard | Standard | Standard |

| Vacuum or Over-pressure after | -1 to +2 bar | -1 to +3 bar | -1 to +2 bar | -1 to +3 bar |

| Function Washing by Inert Gas | Standard | Standard | Standard | Standard |

| Packing Qty | Priced individually |

|---|---|

| OEM Parts | Yes |

Log In