Indutherm VC 12000HTC Large Casting Machine

| Specifications | |

|---|---|

| Brand | Indutherm |

| Model | VC 12000HTC |

| Power Max/Electrical Connection | 40-60 kW (3x400 V) |

| Temperature max. indirect inductive heating HTC | 1850° C |

| Training | Technical Remote Training & After Sales Support Included |

| Crucible Volume | 12 l (14 ) = 30 kg Al / 90 kg Cu / 90 kg steel* |

| For use of molds up to | ø 600 mm / 800 mm h |

| Maximum pressure | 0,3 bar |

| Control system | by LCD-display, full text readout |

| Vibration technology | standard equipment Sweep Mode |

| Programs | 100 |

| Temp. measurement by optical pyrometer | 1300° C |

| Country of Origin | Germany |

Highly efficient operating concept

The right machine for every application

The range of our VC series systems extends from small to very large capacities, from semi-automatic systems to solutions for fully automatic casting production. Sophisticated functional details create the basis for optimizing each casting for its individual properties.

Separate locking systems for “overlapping” casting

All Indutherm VC systems have separate locking systems for the melting and cuvette chambers, enabling significant time savings through “overlapping” pouring: While the cuvette remains in the vacuum chamber for a few minutes after pouring, the next batch can be filled and heated up.

Pneumatic bell lock and automatic locking system

The melting chambers of all VC systems are closed with a pneumatic system. VC 650 V and VC 680 V are also equipped with an automatic locking system.

Automatic cuvette and chamber lift

To swivel in the vacuum chamber, the cuvette inserted is lowered and then docked automatically. When the chamber is opened, the cuvette is raised for easy removal. This means the economical cuvettes can be used without a flange.

Program control for fast and certified productions

Thanks to the control panel with full-text LCD display, all programs and parameters can be set very easily and practically. The semi-automatic systems have temperature programs. The fully automatic systems have a program control system that includes all parameters.

Up to 100 casting programs ensure quick operation and uniform casting results. The parameters are pre-programmed for the most important alloys, e.g. B. for AGS, Alpha Plus, Heraeus, Legor and

Pandor alloys. In practice, this means: Good casting results can be expected from the first cuvette without expensive preliminary tests. The program control and the built-in data printer ensure a high level of security and precise process logging.

Ready for future standards

Like all of our systems, the VC series is equipped with software and interface management that allows remote maintenance and service and forms the basis for future networking with other systems.

Controlling the pressure conditions – important for the perfect casting result

Automatic vacuum and overpressure in the melting and cuvette chambers

The vacuum in the melting chamber ensures that the metal is degassed and prevents unwanted oxidation during melting (an oxygen-poor atmosphere is particularly important when melting copper-containing alloys). The vacuum in the cuvette chamber improves mold filling, especially when casting delicate parts, and prevents annoying air pockets. In addition, the system switches to overpressure in the melting chamber, thus increasing the pressure difference.

Oxidation reduction after casting

This special system eliminates the risk of oxidation while the cuvette cools.

Turbulence reduction software

TRS ensures a faster and more consistent flow of metal. It improves mold filling and prevents parts of the plaster mold from breaking off at critical points and becoming trapped in the casting.

Turbo Pressure / Turbo Pressure PLUS

The turbo pressure function optimizes the casting of very small and delicate objects and guarantees perfect casting with stones in jewelry production. With Turbo-Pressure, a precisely defined and extremely rapid pressure build-up is achieved during pouring. With all program-controlled VC models, Turbo-Pressure is automatically started at the same time, exactly to the second, depending on the program. The Turbo Pressure PLUS system also allows higher and faster pressure build-up.

HSC – High Speed Casting

HSC improves mold filling and surface quality of small parts or those with large and smooth surfaces. HSC makes it possible to cast processed colored stones at low temperatures.

HSC improves mold filling and surface quality of small parts or those with large and smooth surfaces. HSC makes it possible to cast processed colored stones at low temperatures.

Precise temperature control

Dual temperature control

The temperature measurement in both the crucible wall and in the crucible center (integrated in the closure rod) ensures strict adherence to the preselected temperature range.

Cuvette temperature measurement

Up until now, cuvettes with incorrect or different temperatures were a safety risk. When casting very small or delicate parts, the correct cuvette temperature is crucial. Measuring the cuvette temperature (standard for VC 650 V and VC 680 V) now provides the decisive plus in safety: the temperature of the cuvette can be checked with an accuracy of one degree.

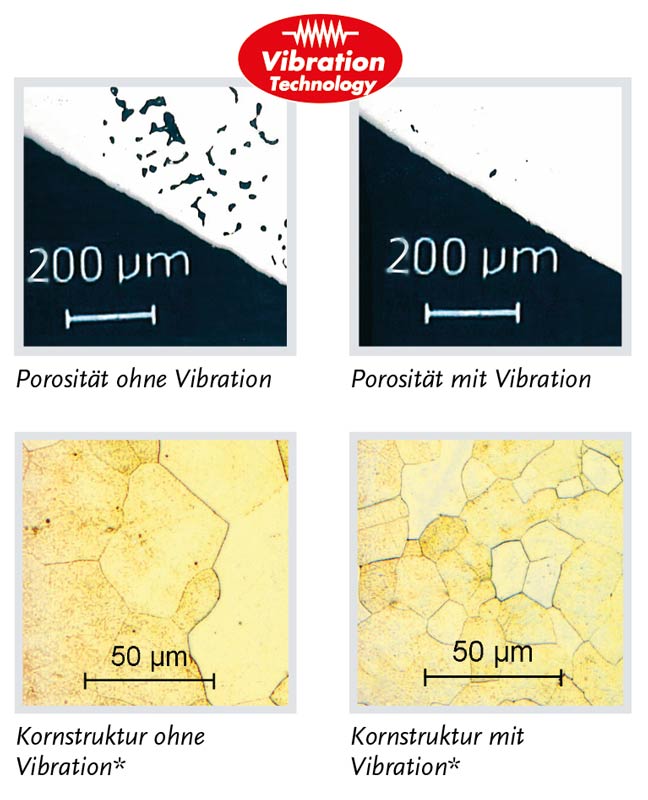

Vibration technology for better casting results

The Indutherm vibration system

- Vibration during casting improves material flow and thus mold filling.

- The density of the castings is higher and more uniform.

- The porosity is significantly reduced.

- 50% smaller grain sizes

- reduced risk of breakages (hot cracks)

- Cast parts have better tension and elastic properties, which makes them easier to process

In practice this means: higher and more consistent quality, less scrap, less post-processing, better formability. A customer in the USA found that the Indutherm vibration technology reduced overall production time, including post-processing, by 25%.

In practice this means: higher and more consistent quality, less scrap, less post-processing, better formability. A customer in the USA found that the Indutherm vibration technology reduced overall production time, including post-processing, by 25%.

| Packing Qty | Priced individually |

|---|

Log In