Optimizing Model Positioning for MJP 3D Wax Printing

Optimizing Model Positioning for MJP 3D Wax Printing

When setting up a build in MJP 3D Wax Printing, precise model positioning is essential. Arranging patterns should align with your intended outcome, which is often a balance of user-specific goals. Factors such as dimensional accuracy, print quality, material efficiency, single-pattern build speed, and maximum throughput must all be considered, as these goals can sometimes conflict or require trade-offs. For instance, achieving the highest print quality may require more material or longer print times.

Positioning Guidelines for Different Geometries

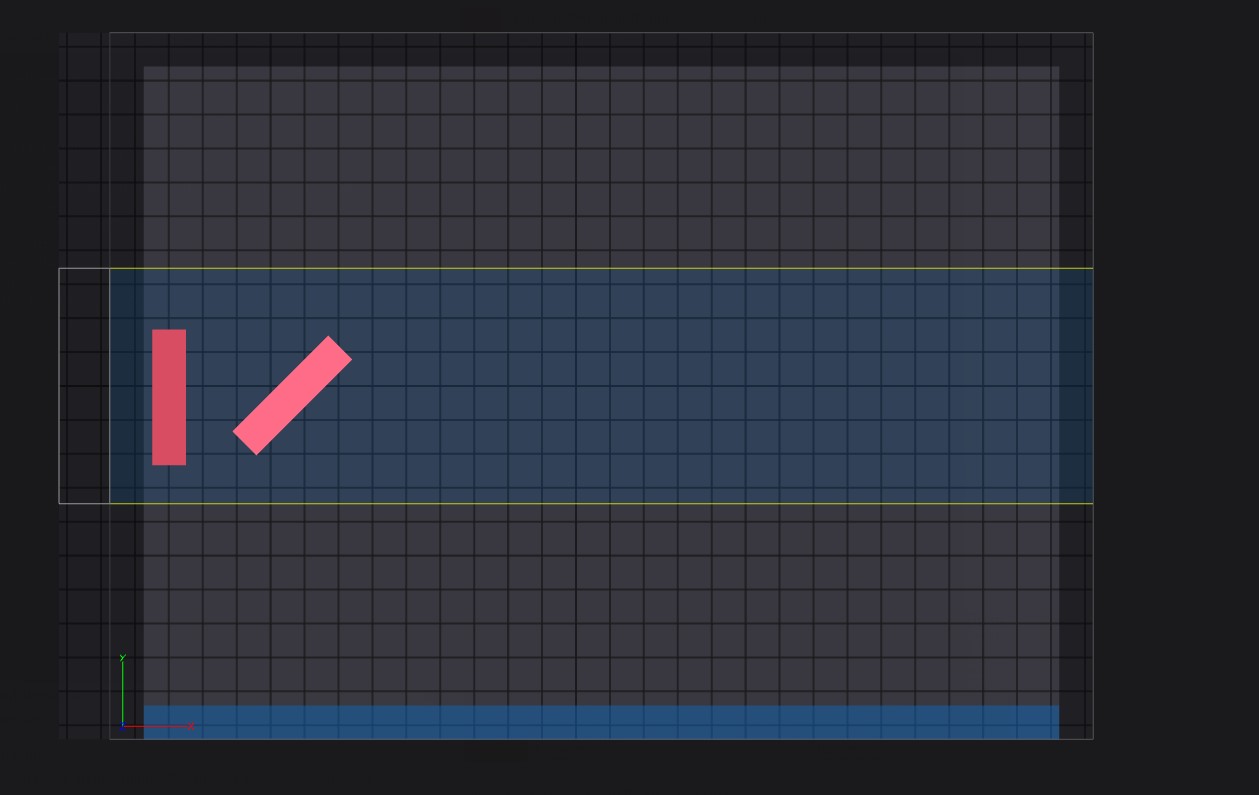

- Long Flat Edges:

- Models with long flat edges should be oriented so these edges are not parallel with the verification strip/wall. Instead, angle the long edge relative to the wall to reduce initial surface

contact with the planarizer, which helps in achieving better print consistency and quality.

- Fine Details and Text:

- Delicate features, such as embossed or debossed text, print best when facing upward. If downward orientation is required, minimize instances where the text is aligned vertically along the X or Y axis, as this can impact sharpness and legibility.

- Large Flat Surfaces:

- For areas exceeding 2–3 square inches, avoid positioning them parallel to the build plate to prevent delamination between support and build surfaces. Instead, rotate the model slightly (about 10 degrees in both the X and Y axes) to reduce the surface area per layer and improve overall print quality.

- Mitigating the Stair-Stepping Effect:

- Surfaces should either be precisely parallel/perpendicular or set at an angle of over 10 degrees relative to the build plate to avoid the "stair-stepping" effect. For shallow angles (less than 10 degrees), this visual artifact becomes more pronounced. Use the move tool to align a flat surface with the build plate. If the surface is large, avoid placing it directly on the plate to prevent delamination risks.

By following these guidelines, you can achieve an optimized print that balances quality, speed, and material use, tailored to your specific project requirements.

Log In